Laser Cutting Equipment for Dummies

Wiki Article

In regards to modern-day producing, the precision and performance of laser slicing technological innovation are definitely activity-shifting. Laser slicing equipment have revolutionized industries by providing a way of slicing components with unparalleled precision. When you’ve at any time marveled at the intricate types on metal or wondered how sophisticated shapes are made so seamlessly, it’s typically the do the job of the industrial laser cutting machine.

Enable’s get started with the fundamentals: a laser cutter is a Instrument that works by using a laser beam to chop components. This beam is very concentrated and generates significant temperatures to melt or vaporize the fabric, producing specific cuts. In contrast to traditional procedures, which might use mechanical blades, a laser cutter offers a standard of accuracy that is nearly unmatched. Imagine looking to carve a fragile sample by using a hammer—Plainly, a laser cutter is a lot extra refined!

Industrial laser chopping normally takes this technologies to another level, offering methods for big-scale functions. These equipment are created to deal with hefty elements and higher output volumes, ensuring that even one of the most demanding initiatives are completed with substantial efficiency. Think of it as the distinction between utilizing a precision knife for sensitive paper crafts and a powerful observed for chopping via thick Wooden.

The Best Guide To Precision Laser Cutting

On this planet of CNC laser chopping, the “CNC” stands for Computer Numerical Manage. This technologies allows for automated and highly specific cuts by subsequent electronic designs. In the event you’ve at any time utilized a pc to attract after which found that drawing arrive at everyday living, CNC laser slicing is effective in the same way, translating electronic types into Actual physical cuts. It’s like having a Digital designer Together with the precision of the laser.

On this planet of CNC laser chopping, the “CNC” stands for Computer Numerical Manage. This technologies allows for automated and highly specific cuts by subsequent electronic designs. In the event you’ve at any time utilized a pc to attract after which found that drawing arrive at everyday living, CNC laser slicing is effective in the same way, translating electronic types into Actual physical cuts. It’s like having a Digital designer Together with the precision of the laser.The Laser Cutting Technology Ideas

Precision laser slicing is not almost making cuts; it’s about earning them proper each and every time. The laser might be adjusted to realize diverse depths and widths, making certain that each cut is exactly where by it has to be. This is certainly important for apps in which even a slight deviation could lead on to important troubles. Imagine it being a surgeon’s scalpel, exactly where precision is not simply essential but Completely critical.

Precision laser slicing is not almost making cuts; it’s about earning them proper each and every time. The laser might be adjusted to realize diverse depths and widths, making certain that each cut is exactly where by it has to be. This is certainly important for apps in which even a slight deviation could lead on to important troubles. Imagine it being a surgeon’s scalpel, exactly where precision is not simply essential but Completely critical.Laser cutting gear comes in various types, each personalized to distinct needs. No matter if You'll need a small desktop model for interest jobs or a huge industrial device for manufacturing facility use, there’s a laser chopping Option to choose from for you. These devices vary in electricity, pace, and capabilities, so it’s important to choose the ideal one particular in your distinct software.

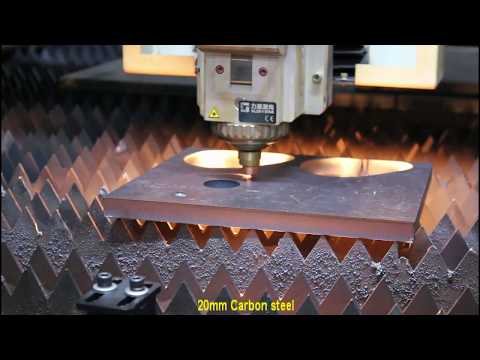

Sheet steel laser cutters really are a Exclusive classification of laser cutting equipment designed especially for slicing metal sheets. They're extensively Utilized in industries starting from automotive to aerospace because of their power to manage metallic with precision and velocity. Picture a sheet of steel similar to a blank canvas, and also the laser cutter as the artist who makes sophisticated and delightful designs with outstanding accuracy.

Laser slicing products and services are One more essential facet of this technological know-how. Not Absolutely everyone wants to take a position in their unique laser chopping machine, particularly when they only need to have occasional cuts or deficiency the Area for such equipment. Lots of firms provide laser reducing services where you can ship your types and possess them cut with superior precision. It’s like outsourcing your artwork to a skilled Skilled.

Laser slicing methods integrate many components to provide read full article the desired effects. Through the laser source for the cutting mattress, plus the Handle computer software, each individual Portion of the method will work with each other to guarantee a flawless operation. It’s a tiny bit just like a symphony orchestra, where by Each individual musician has a selected function, and only by Doing the job collectively do they develop a harmonious general performance.

In regards to laser chopping technological innovation, Laser Cutting Machine the evolution has been rapid and remarkable. Initially made use of largely for reducing metals, these devices now take care of a wide range of products which include plastics, Wooden, as well as fabrics. This flexibility would make laser slicing technology a useful Software in numerous industries. Envision using a Swiss Army knife that could take care of nearly any content—This is certainly what present day laser slicing technological know-how offers.

The precision of laser cutting machines is really impressive. They're able to Reduce products to in just microns with the supposed design, guaranteeing that even the most intricate information are preserved. This degree of precision is especially beneficial in industries in which actual measurements are crucial. Visualize it because the difference between a tailor-made go well with and off-the-rack clothes—the in shape is just perfect anytime.

Excitement About Laser Cutting Equipment

Another advantage of laser chopping technologies is its performance. Compared with classic reducing techniques That may need numerous actions or applications, laser slicing usually completes the activity in one go. This not only hurries up production but will also lessens substance squander. It’s like using a large-speed train that gets you to the vacation spot promptly and effectively without any unnecessary stops.Within the context of industrial applications, the robustness of laser slicing equipment is critical. These equipment are constructed to endure the calls for of constant operation, typically running 24/7 in superior-volume settings. Their longevity guarantees constant overall performance and dependability, which happens to be essential for keeping creation schedules. It’s like using a hefty-obligation truck that reliably delivers goods working day right after day.

On the list of extraordinary areas of laser cutting is its power to generate cleanse and specific edges. This reduces the need for submit-processing, such as sanding or finishing, which may be time-consuming and costly. The end result can be a smooth, finished products that often involves minimal further Laser Cutting Machine do the job. Envision finishing a craft task without any glue spills or rough edges—it’s that thoroughly clean!